Industrial Pressure Reducing Station Services

MOQ : 1 , , Unit

Industrial Pressure Reducing Station Services Specification

- Working Pressure Range

- Up to 60 bar

- Corrosion Resistance

- Yes

- Installation Type

- Field Installation

- Design Standard

- ASME / IS / API

- Service Location

- Pan India

- Output Pressure Range

- 0.5 to 20 bar

- Service Mode

- Offline / Onsite

- End Connection

- Flanged / Screwed

Industrial Pressure Reducing Station Services Trade Information

- Minimum Order Quantity

- 1 , , Unit

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Industrial Pressure Reducing Station Services

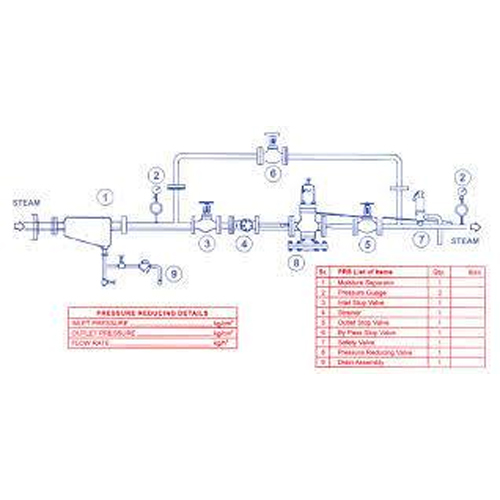

We have become the famous entity of the industry by proficiently manufacturing and exporting the best quality Industrial Pressure Reducing Station. It is made by our experts using supreme quality materials procured from the authorized vendor of market. In accordance with the industry quality standards, our offered system is tested by our inspectors before the final delivery in the market. It is widely used for reducing the pressure of gas. Our customers can avail this Industrial Pressure Reducing Station from us at a reasonable price.Precision Control for Industrial Applications

Our pressure reducing stations are designed to deliver highly accurate output for diverse industrial processes. Serving sectors from manufacturing to utilities, we provide systems built for stable pressure control, safeguarding equipment and ensuring process integrity. With our adherence to global standards and flexible connectivity, your facility receives both dependable operation and seamless integration.

Expert Onsite Installation and Service Across India

We offer offline and onsite field installation of our pressure reducing stations at any industrial facility in India. Our technicians follow stringent protocols, delivering rapid, safe deployment anywhere in the country. Our commitment includes comprehensive after-sales support for ongoing system efficiency and reliability.

FAQs of Industrial Pressure Reducing Station Services:

Q: How does the industrial pressure reducing station service process work?

A: Our process begins with an onsite assessment to determine your pressure requirements. We design the system according to ASME, IS, or API standards, select suitable end connections, and install the equipment at your field location. After installation, we test and commission the station to ensure precise output within 0.5 to 20 bar.Q: What are the main benefits of using a pressure reducing station in my facility?

A: Installing a pressure reducing station helps protect downstream equipment, enhances operational safety, and ensures the optimal performance of industrial processes. Our corrosion-resistant design ensures durability and longevity even in harsh environments.Q: When should I consider installing or upgrading a pressure reducing station?

A: You should consider this service when expanding plant capacity, modifying pressure systems, or experiencing issues like equipment wear due to high pressure. Regular audits may also reveal when an upgrade to industry standards is needed for safety and compliance.Q: Where are your industrial pressure reducing station services available?

A: We offer our services to industrial clients throughout India, providing both onsite and offline installations and full technical support at any location.Q: What is the typical usage of a pressure reducing station in industrial settings?

A: These stations are commonly used to regulate and reduce inlet pressures of up to 60 bar to safer, controlled output pressures (0.520 bar), serving various operational units such as boilers, process lines, and utility distribution networks.Q: How do you ensure corrosion resistance in your pressure reducing stations?

A: We use premium materials and protective coatings as part of the design, ensuring every installation is resilient against corrosive industrial gases and harsh operating conditions.Q: What standards and end connections are supported by your stations?

A: Our stations are engineered to ASME, IS, and API standards and can be configured with either flanged or screwed end connections to match your pipeline system requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry